Εργαστηριακοί έλεγχοι Cube

-

Τιμή

.jpg)

Real Life Stress

CUBE Test Laboratory

Bumps, hard braking and real life stress. To ensure high quality each bike and every relevant component is exhaustively tested by our in-house test lab.

No Excuses: The Brakes Always have to Work

That’s why our engineers test various braking systems in our labs in order to guarantee perfect braking, stability and wear and tear resistance. Weather conditions are taken into account as well, which is why every brake is tested in dry and wet conditions. Once we're satisfied that a system works perfectly in both conditions, we move onto the second phase – checking durability. To test this, we automatically repeat 3000 braking cycles. Only brakes that pass this test - by showing minimal wear and tear - are used on our bikes.

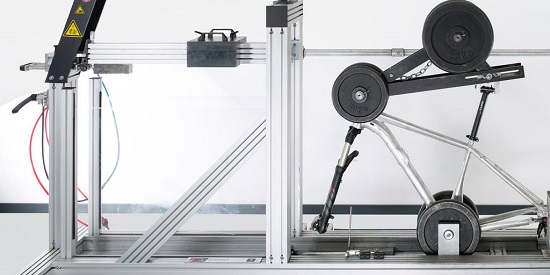

Complete bikes are tested on our roller drum test rig. We place the bike – fitted with production components – on the drum and add weights to the handlebar, saddle and pedals (140kg in total) to simulate the weight of a rider and all of his luggage. The drums rotate to simulate typical road surface bumps so that the bike “rides” a given number of miles and covers certain obstacles. In total, each bike covers hundreds of miles and has to overcome 1.5 million obstacles.

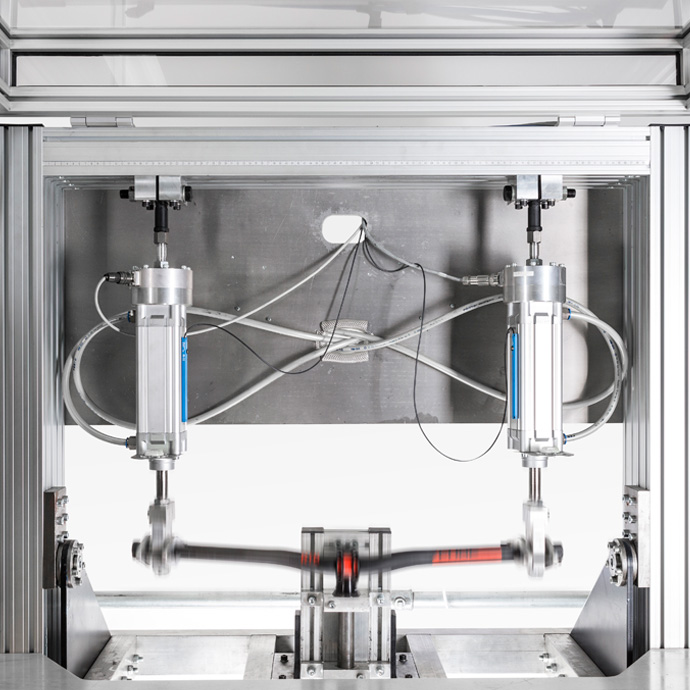

The reliability and durability of a handlebar, stem and seat post have to be 100% for every bike.

That is why every component is tested twice, once during production and a second time in CUBE’s very own testing laboratory. The current standards are only a foundation; we do more intense testing in order to ensure the safety of our bikes in all applications.

The demands put on bikes are even higher now because riding speed, distance and total weight are all higher than on a traditional bike. The components we build in have to match this higher load. The various test rigs we use reproduce the realistic levels of strain, pressures and angles that a typical rider would use. To take the handlebar as an example, a parallel force is applied at both ends.

Special Test Lab Road Race

Sprinting for the finish line under the rider’s full power is a challenge for any bike. At CUBE’s test labs, all components that contribute to safety undergo extensive testing to ensure they reach our high standards.

A bike has to cope with huge forces through its frame, particularly during a sprint. That’s why we test this kind of load in our lab. Just like normal pedalling – only more so – force is exerted sinusoidally on the crank arm to simulate the forces generated during a sprint finish. This test takes more than 16 hours. Over the course of a normal ride, even more force is exerted... so we test it again. At this point we increase the force acting on the pedals by another 25% – and the bike has to survive 10,000 cyclesat this level.

Special Test Lab Mountainbike

The head tube is a particularly vulnerable area on a moutain bike, because large loads transmitted by the suspension fork are passed directly through it. That's why we test intensively with this kind of load separately, on a specific machine built just for this purpose. A realistic load is put on a fork to simulate braking, jumping and obstacles – in total, the head tube has to endure 50,000 of these cycles without damage before it can be released for production.

Δεν υπάρχουν προϊόντα σε αυτή την κατηγορία.